Specifications

| SIZE | STOCK NUMBER | WEIGHT/100 PIECES | MINIMUM CLIPS REQUIRED | TORQUE IN LBS. FT.* | TURN BACK LENGTH |

|---|---|---|---|---|---|

| 1/8″ | DFWRC125 | 5 lbs. | 2 | 4.5 lbs. | 3 1/4″ |

| 3/16″ | DFWRC187 | 10 lbs. | 2 | 7.5 lbs. | 3 3/4″ |

| 1/4″ | DFWRC250 | 18 lbs. | 2 | 15 lbs. | 4 3/4″ |

| 5/16″ | DFWRC312 | 31 lbs. | 2 | 30 lbs. | 5 1/4″ |

| 3/8″ | DFWRC375 | 46 lbs. | 2 | 45 lbs. | 6 1/2″ |

| 7/16″ | DFWRC437 | 73 lbs. | 3 | 65 lbs. | 7″ |

| 1/2″ | DFWRC500 | 73 lbs. | 3 | 65 lbs. | 11 1/2″ |

| 9/16″ | DFWRC562 | 96 lbs. | 3 | 95 lbs. | 12″ |

| 5/8″ | DFWRC625 | 104 lbs. | 3 | 95 lbs. | 12″ |

| 3/4″ | DFWRC750 | 150 lbs. | 4 | 130 lbs. | 18″ |

| 7/8″ | DFWRC875 | 244 lbs. | 4 | 225 lbs. | 19″ |

| 1″ | DFWRC100 | 270 lbs. | 5 | 225 lbs. | 26″ |

*Torque values shown are based on clean, unlubricated threads. Wire rope clips are not designed for load carrying purposes, therefore working load limits have not been established.

Note: Malleable Wire Rope Clips made according to Federal Specification FF-C-450 G, Type 1, Class 2. Forged Wire Rope Clips made according to Federal Specification FF-C-450 G, Type 1, Class 1.

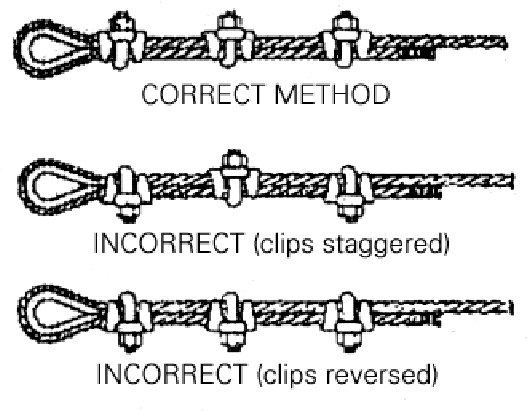

Proper Use